Bosch has issued a statement announcing that it will add to its previously announced investments in semiconductor production to address the ongoing chip shortage, Techcruch reported. According to the announcement, the company will add $296 million to its new manufacturing facilities, in addition to the $473 million it pledged to invest last year in 2022.

Bosch, the German auto parts supplier that officially completed a new 12-inch fab in Dresden, Germany, only last June, announced in late October last year that it would invest more than 400 million euros in 2022 to expand its Dresden, Germany, Reutlingen fab and build a chip test center in Penang, Greater Malaysia.

Most of the funds announced by Bosch last year were earmarked for Bosch’s new 300 mm wafer fabrication facility in Dresden, with about $57 million going to Bosch’s Reutlingen wafer fab near Stuttgart, which began production in December.

Between now and 2025, this new funding will be used almost entirely in Reutlingen to create new production space and a total of 44,000 square meters of modern cleanroom space, a move the company is taking in response to the growing demand for semiconductors and microelectromechanical systems (MEMS) sensors for the automotive and consumer electronics markets.

“Bosch is already more than a chip manufacturer for automotive applications,” said Markus Heyn, a member of the Bosch Management Board and chairman of the Mobility Solutions business unit, in a statement. “This is a position we intend to consolidate.”

(Clean rooms are specially constructed and enclosed to allow strict control of airborne particles, temperature, lighting, noise, air pressure and other environmental factors. Because Bosch’s semiconductors, like many others, are made from silicon carbide, the manufacturing process requires jue to cleanliness – silicon is found in sand and must be refined before it can be used in manufacturing. It’s a very jing process, and even tiny bits of dust that fall on a chip at the wrong time can be completely discarded.)

“We are systematically expanding our semiconductor manufacturing capacity in Reutlingen,” said Dr. Stefan Hartung, chairman of the Bosch Management Board, in a statement. “This new investment will not only strengthen our competitive position, but will also benefit our customers and help address the crisis in the semiconductor supply chain.”

The Reutlingen fab will produce 6-inch and 8-inch wafers; not as many 6-inch wafers as 8-inch or 12-inch are currently in use, but the process can reduce production costs for semiconductor products such as LEDs and sensors. Since 2019, there has been a shortage of 8-inch wafers in particular, which are mainly used in areas such as sensors, MCUs and wireless communication chips. Bosch said the expansion in Reutlingen will meet the growing demand for MEMS and silicon carbide power semiconductors in the automotive and consumer sectors.

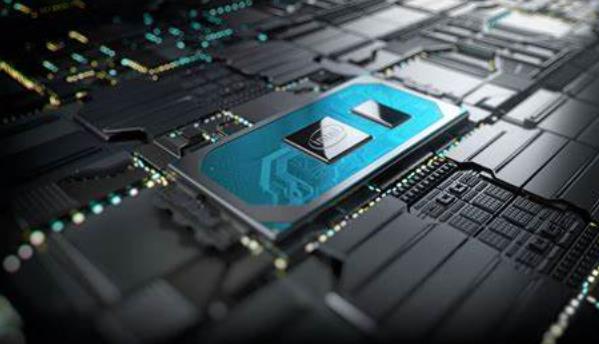

Bosch’s Dresden facility will produce more 12-inch silicon chips for high-performance products such as CPUs, logic ICs and memories.

“The artificial intelligence approach combined with connectivity has helped us achieve continuous, data-driven improvements in manufacturing to produce increasingly better chips,” Heyn said. “This includes developing software to enable automatic classification of defects. Bosch also uses artificial intelligence to enhance material flow. With its high level of automation, the very advanced production environment in Reutlingen will safeguard the future of the plant and the jobs of the people who work there.”

Bosch also plans to expand its existing power supply facilities and emphasizes that the new production area will be operational by 2025.