The types of capacitors can be divided into: non-polar variable capacitor, non-polar fixed capacitor, polar capacitor, etc. in principle, they can be divided into: CBB capacitor (polyethylene), polyester capacitor, ceramic chip capacitor, mica capacitor, monolith capacitor, electrolytic capacitor, tantalum capacitor, etc.

Non-polarity variable capacitor

Production process: The rotatable moving piece is a ceramic piece with metal film plated on the surface, and the fixed piece is a ceramic base with metal film plated; the moving piece is a coaxial metal piece, and the fixed piece is an organic film piece as a medium.

Advantages: easy to produce, low technology content.

Disadvantages: large volume, small capacity

Use: Change the oscillation and resonant frequency circuit. FM, AM, transmitter/receiver circuits

Non-polarity non-inductance CBB capacitor

Production process: 2 layers of polypropylene plastic and 2 layers of metal foil are alternately sandwiched and then bundled.

Advantages: non-inductive, good high frequency characteristics, small size

Disadvantages: not suitable for large capacity, high price, poor heat resistance.

Uses: coupling / oscillation, audio, analog / digital circuits, high frequency power supply filtering / decoupling.

Non-polarized CBB capacitor

Production process: 2 layers of polyethylene plastic and 2 layers of metal foil are alternately sandwiched and then bundled.

Advantages: inductive, good high frequency characteristics, small size.

Disadvantages: not suitable for large capacity, relatively high price, poor heat resistance.

Uses: coupling / oscillation, analog / digital circuits, power supply filtering / decoupling.

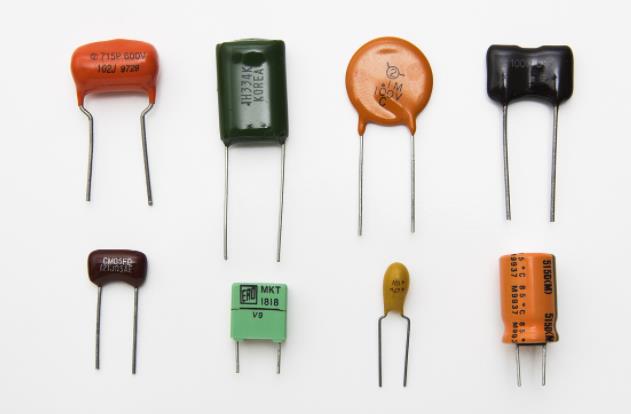

Non-polarity porcelain chip capacitor

Production process: thin porcelain wafer with two sides dado metal film silver and become.

Advantages: small size, high withstanding voltage, low price, high frequency (there is a kind of high frequency capacitor)

Disadvantages: fragile, low capacity

Uses: high frequency oscillation, resonance, decoupling, audio

Non-polarity mica capacitor

Production process: two layers of metal film coated on mica sheet

Advantages: easy to produce, low technical content.

Disadvantages: large volume, low capacity Uses: oscillation, resonance, decoupling and less demanding circuits Non-polarized monolithic capacitors are smaller than CBB, others are the same as CBB, with sense

Usage: analog/digital circuit signal bypass/filtering, audio.

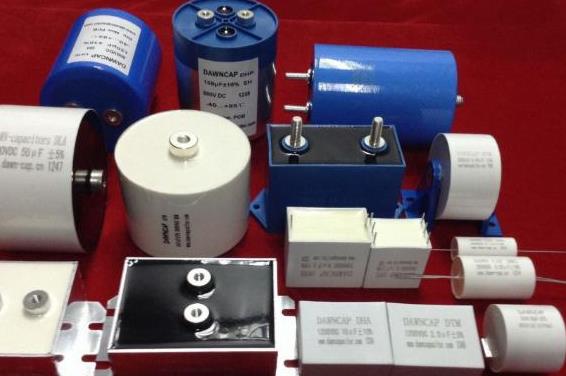

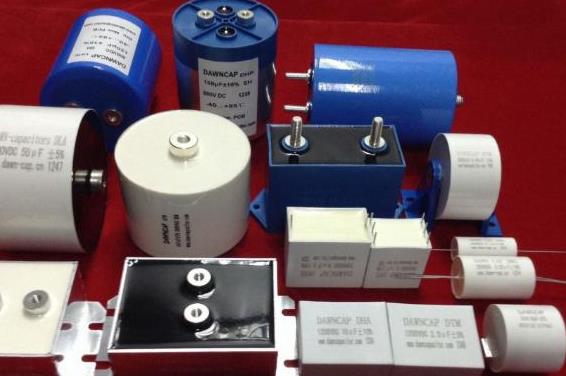

Polarized electrolytic capacitor

Production process: Two aluminum strips and two insulating films are laminated to each other, and then dipped in electrolyte.

Advantage: High capacity.

Disadvantage: Bad high frequency characteristics.

Uses: low frequency inter-stage coupling, bypass, decoupling, power supply filtering, audio.

Tantalum capacitor

Production process: Tantalum metal is used as the positive electrode, and metal is sprayed on the outside of electrolyte as the negative electrode.

Advantages: good stability, large capacity, good high frequency characteristics.

Disadvantage: high cost..

Uses: High-precision power supply filtering, signal inter-stage coupling, high-frequency circuit, audio circuit.

Polyester (Polyester) Capacitor

Symbol: CL

Capacitance: 40p–4u

Rated voltage: 63–630V

Main features: small volume, large capacity, heat and humidity resistance, poor stability.

Applications: low frequency circuits with low requirements for stability and loss.

Polystyrene capacitor

Capacitance: 10p–1u

Symbol: CB

Rated voltage: 100V–30KV

Main features