Light emitting diodes can also be divided into ordinary monochrome light emitting diodes, high brightness light emitting diodes, ultra-high brightness light emitting diodes, color changing light emitting diodes, flashing light emitting diodes, voltage controlled light emitting diodes, infrared light emitting diodes and negative resistance light emitting diodes.

LED control modes are constant current and constant voltage, there are a variety of dimming methods, such as analog dimming and PWM dimming, most of the LEDs are using constant current control, which can keep the LED current stable and not easily subject to changes in VF, which can extend the life of LED lamps.

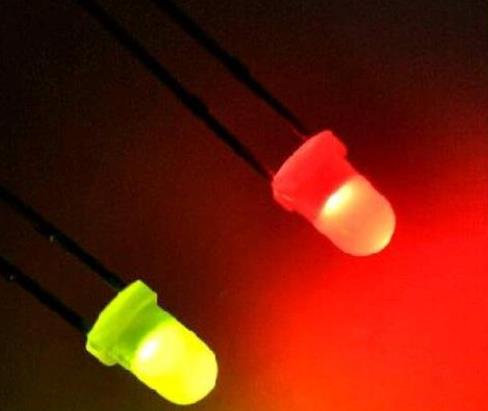

Monochrome Light Emitting Diodes

Common monochrome light-emitting diodes

Ordinary monochrome light-emitting diodes have the advantages of small size, low operating voltage, small operating current, uniform and stable light, fast response, long life, etc., and can be driven by a variety of DC, AC, pulse and other power to light. It is a current-controlled semiconductor devices, the use of a suitable series of current-limiting resistors.

Ordinary monochrome light-emitting diode light-emitting color and wavelength of light, and the wavelength of light depends on the manufacture of light-emitting diodes used in semiconductor materials. Red light-emitting diode wavelength is generally 650 ~ 700nm, amber light-emitting diode wavelength is generally 630 ~ 650nm, orange light-emitting diode wavelength is generally 610 ~ 630nm, yellow light-emitting diode wavelength is generally about 585nm, green light-emitting diode wavelength is generally 555 ~ 570nm.

High brightness monochromatic

light-emitting diodes and ultra-high brightness monochromatic light-emitting diodes use different semiconductor materials than ordinary monochromatic light-emitting diodes, so the intensity of light is also different. Usually, high-brightness monochromatic LEDs use materials such as gallium arsenide (GaAlAs), ultra-high-brightness monochromatic LEDs use materials such as gallium indium arsenide phosphorus (GaAsInP), and ordinary monochromatic LEDs use materials such as gallium phosphide (GaP) or gallium arsenide phosphorus (GaAsP).

Color Changing Light Emitting Diodes

Color-changing light-emitting diodes are light-emitting diodes that can change their color. Color-changing light-emitting diodes can be divided into two-color light-emitting diodes, three-color light-emitting diodes and multi-color (with red, blue, green, white four colors) light-emitting diodes.

Color-changing light-emitting diodes according to the number of pins can be divided into two-terminal color-changing light-emitting diodes, three-terminal color-changing light-emitting diodes, four-terminal color-changing light-emitting diodes and six-terminal color-changing light-emitting diodes.

Scintillation Light Emitting Diodes

Blinking light-emitting diode (BTS) is a special light-emitting device composed of CMOS integrated circuit and light-emitting diode, which can be used for alarm indication and under-voltage, over-voltage indication.

Blinking light-emitting diodes in use, without external components, as long as the pin terminals with the appropriate DC working voltage (5V) can be blinking light.

Infrared light-emitting diodes

Infrared light-emitting diodes, also known as infrared emitting diodes, which can be converted directly into infrared light (invisible light) and can be radiated out of the light-emitting devices, mainly used in a variety of light control and remote control transmitter circuit.

Infrared light-emitting diode structure, principles and ordinary light-emitting diode is similar, but the use of different semiconductor materials. Infrared light-emitting diodes usually use gallium arsenide (GaAs), gallium arsenide aluminum (GaAlAs) and other materials, using fully transparent or light blue, black resin package.

Commonly used infrared light-emitting diodes are SIR series, SIM series, PLT series, GL series, HIR series and HG series, etc.

Ultraviolet Light Emitting Diodes

UV LEDs (Ultraviolet Light Emitting Diodes) based on semiconductor materials have the advantages of energy saving, environmental protection and long life, and have significant applications in the fields of sterilization, medical and biochemical testing. In recent years, semiconductor UV photovoltaic materials and devices have attracted increasing attention worldwide and have become R&D hotspots.

The 3rd International Workshop on Ultraviolet Materials and Devices (IWUMD I 2018), hosted by the Institute of Semiconductors, Chinese Academy of Sciences, was held in Kunming, Yunnan Province, China, on December 9-12, 2018, with more than 270 delegates from 12 countries attending the conference. The conference brought together a number of leading experts from home and abroad in the field of UV light-emitting diode materials and devices to present their latest research and development results.

At present, UV-LED is the main trend in the development of nitride technology and the development of third-generation semiconductor material technology, with broad application prospects. In order to accelerate the development of the third-generation semiconductor solid-state UV light source, the Ministry of Science and Technology of China (MOST) has launched the Key Research and Development Program (2016YFB0400800) for the key technology of the third-generation semiconductor solid-state UV light source materials and devices.

The support of the National Key R&D Program and the International Symposium on UV Materials and Devices will play a positive role in accelerating the market application of the third-generation semiconductor UV light source in China and driving the development of UV semiconductor light-emitting diode materials and device technologies and industrialization in China.

Organic Light Emitting Diode (OLED)

In 1987, Kodak’s Deng Qingyun and others successfully prepared low-voltage, high-brightness organic light-emitting diodes (OLEDs), showing the world for the first time the prospects of OLEDs in commercial applications'”. 1995, Kido published in science magazine white organic light-emitting diodes (wOLEDs) article, although the efficiency is not high, but unveiled the prelude to OLED lighting research. After decades of development, the efficiency and stability of OLEDs have long met the requirements of small-size displays, and are favored by many high-end instrumentation, cell phone and mobile terminal companies, and large-size technology is becoming increasingly sophisticated.

The development of OLED materials is the basis for the booming OLED industry. The earliest OLED light-emitting materials are fluorescent materials, but fluorescent materials can only reach the upper limit of theoretical internal quantum efficiency of 25% due to spin blocking. 1998, Ma and Forrest and Thompson have reported the application of phosphorescent materials in OLED materials, thus opening the way for breaking the law of spin statistics and utilizing 100% of the energy of all excitons. However, phosphorescent materials also have certain problems, as they contain precious metals, the price is very high and the stability of the blue material has long been stagnant.

In 2009, Professor Adachi of Kyushu University in Japan first introduced thermally activated delayed fluorescence (TADF) materials into OLEDs, which have a very low single trilinear energy gap and can achieve 100% theoretical internal quantum efficiency through reverse inter-system scattering (RISC) of trilinear excitons. The increasing sophistication of material systems and device structures has led to the emergence of OLEDs in the display field. On the other hand, WOLEDs have a series of advantages such as high luminous efficiency, adjustable spectrum, low blue light content and surface light source, which are expected to become the new trend of future health lighting as a high efficiency light source with low color temperature and no blue harm.